Description

Freezing is achieved through direct contact with a surface cooled to -75/-80°C.

To freeze the plasma, containers are lowered vertically into slot-like compartments with walls cooled to at least -75°C.

VERTICAL PLASMA FREEZING

– Simplifies container loading;

– Prevents operator exposure to intense cold from the compartments;

– Avoids the formation of air bubbles inside the container;

– Minimizes the risk of container damage;

– Produces a tile-shaped frozen container;

– Requires no maintenance, as no ice forms around the slots or holding pads;

– Ensures absolute temperature stability within the -75°C to -80°C range.

CONSTRUCTION:

The inner chamber consists of 6 compartments (in model KPFF24B) or 12 compartments (in model KPFF48B), made of AISI 304 stainless steel with a polished external surface, specially treated for enhanced durability and featuring rounded corners for hygienic maintenance (optionally available in AISI 316).

The outer chamber is made of glazed AISI 304 stainless steel.

Thermal insulation is free from CFC and HCFC compounds, with a density of 40 kg/m³ and an average thickness of 175 mm.

AUTOMATIC LOADING (Optional Feature)

Upon closing the lid, deflectors move automatically, compressing the compartments for optimal freezing.

PROCESS TRACEABILITY (Optional Feature)

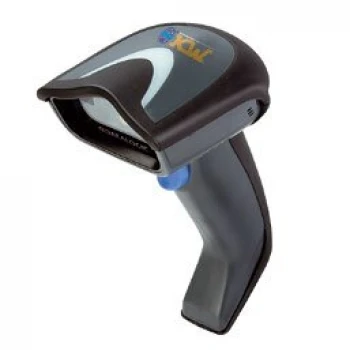

The deep freezer can be equipped with an electronic recorder and a barcode reader; the user can set a working schedule for each freezing batch, specifying:

a) individual plasma units;

b) operator;

c) temperature shift curve.

All data can be exported both in printed and digital formats, ensuring complete traceability of the plasma container freezing batch.

RTS TEMPERATURE RECORDING SYSTEM (Ordered Separately)

Automatic data capture for fresh plasma containers using a barcode or RFID reader.

7-inch TFT touch screen display with dedicated PC-compatible software and a high-speed system board.